Why Busbars in Electric Vehicles?

What is a Busbar?

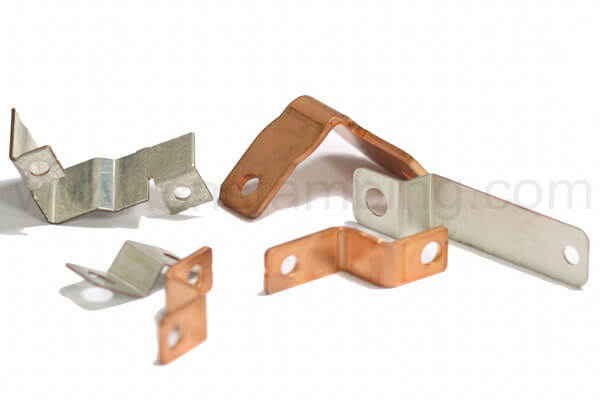

The busbar (or busbar) is an electrical component that makes complex power distribution simpler, more economical, and more flexible. Busbars are solid metal rods used to carry electrical current. It typically made from corrosion-resistant copper, brass, or aluminum. Copper busbars typical oxidize over time but remain conductive. That is why coating busbars is so importance to prevent oxidation. Busbars come in different sizes and shapes, including flat bars, solid rods, and hollow tubes. Among of them, flat or hollow shapes generally being more suitable for high-current applications. Whether it’s a flat bus bar, a solid busbar, or a rod, it dissipates heat more efficiently due to its features that are wider than cables but 70% shorter in height. Additionally, they can carry more current than cables of the same cross-sectional area. These properties make busbars ideal for some high-voltage connections in electric vehicles (EVs) and a key component of future automotive electrical architectures.

Why Busbars in Electric Vehicles?

With the development of electric vehicles, manufacturers have discovered that busbars are an ideal solution to improve the conductivity of electric vehicles. Busbar are typical located within switchgear, panels, and busbar enclosures for local high-current distribution. The benefits of using busbars in electric vehicles are as follows:

- Occupies less space, highly flexible, No need for routine maintenance

Every sensor, actuator, and electrical/electronic device in the vehicle requires power and data cables, along with all the packaging space that comes with them. Due to the structure of the flat conductor, the busbar is not as tall as the cable, and its weight and packaging space are more smaller. No routine maintenance is required, and expansion or renovation is faster;

- Meet the needs of automated assembly, low cost, high safety

Although most automotive assembly has been fully automated, wiring installation is still a largely manual tasks. The cable’s flexibility makes it ubiquitous, which makes it difficult for a robotic arm to grasp the wiring harness and place it correctly in the vehicle. Compared with a wire harness, it is simpler to for a robot to move a busbar into the coreect place.

Automated assembly is cheaper and safer from a labor perspective, it requires fewer installation materials. Besides, it can easily add or relocate power supplies without any downtime;

- Carry more current and dissipate heat more efficiently than cables.

Busbars can carry more current due to their shape and structure. Equipment manufacturers are looking to increase the power of electric vehicle batteries to reduce charging times. The busbar can support 15% more power than a cable with the same cross-sectional area. In addition, the busbar’s larger surface area dissipates heat more efficiently than the entire length of the cable, another advantage for manufacturers looking to increase power levels.

In Conclusion

Today, busbars have proven valuable as battery interconnects, connecting short distances between battery modules in modern electric vehicles. As the busbar extends beyond the battery, OEMs must weigh design decisions in the context of their complete electrical/electronic architecture. Architecture will determine whether to use busbars, where to place them, how to connect them to other components, and where to add shielding or flexibility.