Selection of Automotive Wire Terminals and Materials

Definition of Automotive Wire Terminals

The automotive wire terminal is an important part of automotive electrical appliances, which is responsible for the transmission of current, signal and some important data. Furthermore, It also plays a decisive role in the normal operation of the electrical system of the whole vehicle.

With the rapid development of the automotive industry, the role of automotive wire terminals has been well known by more people. Thus, various electrical appliances with different characteristics are emerging in the automotive. Under this situation, the requirements for the electrical performance of the automotive wire terminal are also higher and higher. It occupies an extremely important position in the automotive wiring harness and the vehicle electrical system.

Types of Crimp Terminals

According to the types of the crimp terminals, we can divide them into chip terminals, cylindrical terminals, wire connector terminals.

The chip series terminals are made of H65Y or H70Y material with a thickness of 0.3~0.5.

The cylindrical series terminals are made of H65Y or QSN6.5-0.1 material with a thickness of 0.3~0.4.

We can divide wire crimp connectors terminals into three forms: U-shaped, fork-shaped and hole-shaped. Among them, U-shaped terminals is the common custom terminals.

It is made of H62Y2, H65Y, H68Y or Qsn6.5-0.1 material with the thickness of 0.4~0.6.

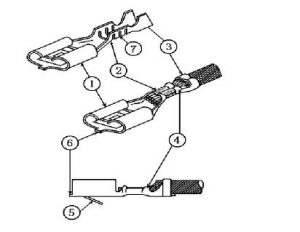

The Structure and Functions of Terminals

- Contact end (contact part): the part that contacts the power supply with the pin of the pin holder;

- Wire barrel: the part that crimps the conductor;

- Insulation cylinder: the part that fixes the insulation of the wire;

- Bell-shaped inlet sleeve: the part that protects the wire from breakage and surface wear;

- Spear hook: locking hook when inserted into the shell;

- Truncated piece: the residual part after the material tape is cut off;

- Jagged protrusions: grooves in the wire barrel to ensure good wire contact;

Materials Selection of Terminals

The Role of Wire Terminals

Terminals play an important role in connecting wires, passing current and electrical signals. In another words, In the processing of crimp terminal pins, it is necessary to learn to choose stamping terminals of different materials.

Material and Performance of Common Wire Terminals

The automotive wire connector end not only requires stable contact resistance, good mechanical strength and durability, but also a lighter weight, easy to process into smaller size, as well as a certain degree of elasticity.

The common materials of automotive crimp contacts and its characteristics are shown as below details, such as more precious metal, soft, easy to bend, high electrical and thermal conductivity, corrosion resistance, excellent operability.

- Copper (Cu): It is yellow, an alloy of copper and zinc, with 60%~96% copper, good elastic material, acceptable electrical conductivity, good handling, easy to weld.

- Brass (CuZn): It is red, an alloy of copper and tin, good elastic material, the elasticity is between brass and wrinkled bronze, the electrical conductivity is worse than that of brass, it is not sensitive to stress corrosion, and the price is higher than that of brass.

- Tin phosphor bronze (CuSn): It is yellow, good elasticity, good fatigue strength, corrosion resistance, wear resistance, extremely high price, about 5 times that of brass.

- Wrinkled bronze (CuBe): It is silver-white, containing Cu65%, Ni12%, Zn23%, electrical conductivity close to brass, corrosion resistance, strong voltage resistance.

- Copper-nickel-zinc alloy (Cunizn): It is gray, the application temperature can reach 250 ℃, poor electrical conductivity, good elasticity, wear resistance.

- Steel(Fe): It is silver-gray, application temperature up to 650 ℃, corrosion resistance, good strength and good electrical conductivity.

Coating of Common Wire Terminals

- Stannum. Stannum(Sn) is silver-white, dark or shiny. Tin is softer, cheaper, and easier to solder. There are three methods of tinning: pre-tinning, pre-cladding and electroplating. The thickness of the coating is 2pm~12um. Brass or bronze tinned can withstand temperature up to 110°C, but steel tinned up to 190°C.

- Gold. Au plated is the highest quality cladding material. Gold is soft, corrosion-resistant, insoluble in pure acid, has good electrical conductivity, and is more expensive. Therefore, it is more reasonable to selectively use gold-plating process, that is, only gold-plating on the connecting part. Gold plating usually chooses nickel plating first to achieve better anti-corrosion effect. Besides, The thickness of gold plating is generally 0.4m~3.5m.

- Palladium. Palladium (Pd) is a noble metal, and its conductivity is lower than that of gold.

- Nickel. Nickel (Ni) is a silver-white metal with poor conductivity, hard and smooth surface. Nickel-plated copper can withstand temperatures up to 340℃, but nickel-plated brass and bronze can reach 250℃.

- SILVER. Silver (Ag) is a precious metal, shiny, white, soft in texture and good in conductivity. Brass or bronze plated with silver can withstand temperature of 110 ℃, while copper plated with silver can withstand temperature of 250 ℃.

Rules for Selecting Auto Wire Terminals

We should select different plated wire crimp terminals according to different automotive wire connectors and different needs. For equipment requiring higher performance, such as terminals for airbags, ABS, ECU, etc., people preferr to use gold-plated automotive wire terminals to ensure safety and reliability. However, due to cost considerations, it is neccessary to select local gold plating under the premise of meeting performance requirements.

Specific Selection Principles are As Follows:

- Ensure that the wire terminals are reasonably matched with the selected terminal connectors.

- Select proper terminals according to the diameter of the crimped wire.

- Ensure connection reliability. When selecting terminals, it is necessary to ensure good contact with electrical devices and plug-ins, so as to minimize the contact resistance and improve reliability. For example, surface contact is better than point contact, pinhole type is better than leaf spring type. In the design, it is preferable to use a connector with a double spring compression structure (very small contact resistance).

- Impedance matching. Some signals have impedance matching requirements, especially RF signals, which have stricter impedance matching requirements. When the impedance does not match, it will cause signal reflection, which will affect signal transmission. Therefore, when selecting terminals, it is necessary to select terminals with match impedance.

Heju stamping is a precision metal stamping manufacturers with more than 30 years of experience in the precision metal stamping industry. Futhermore, We are specialize in all solving all kinds of complex micro&miniature stamped parts, please contact us to solve your metal stamping project.