Secret to Ensure Safe Driving of New Energy Vehicles-Battery Rupture Discs Manufacturer

With the economy’s and technology’s development, new energy vehicles have become an emerging automotive industry. It can meet people’s pursuit of energy conservation and environmental protection and reduce people’s expenses for using gasoline vehicles. However, the battery explosion-proof problem of new energy vehicles is still a pain point that plagues the industry. Therefore, how to ensure the battery safety of new energy vehicles and avoid safety accidents such as battery explosions has become a problem that the industry needs to focus on. This article will elaborate on the principle and function of how the new energy vehicle battery rupture discs can ensure vehicle safety.

What is the Battery Rupture Discs?

Like its name, the battery rupture disc of a new energy vehicle is a safety device to protect the battery during an emergency. Its function is to open the valve when the battery is overvoltage automatically, or the temperature is too high. And the internal high-pressure gas will be emitted directly to achieve the purpose of explosion protection.

The Principle and Function of Battery Bursting Disc

When the internal temperature of the new energy vehicle battery is too high, the internal chemical reaction of the battery will occur. Then the gas will be generated so that the battery’s internal pressure will continue to increase. In this way, the battery’s internal pressure will be too high. Cause damage to the battery, and in the worst case, will cause the battery to explode. To avoid such a situation, the battery of the new energy vehicle is equipped with a “battery explosion-proof valve.” The function of this valve is to disperse the pressure generated inside the battery to the outside world, thereby ensuring the safety of the battery.

The principle of the battery bursting disc is straightforward: when the pressure inside the battery suddenly increases, or the temperature rises rapidly, the valve will automatically trigger, pop open, and emit high-pressure gas to the outside world. Since the battert bursting disk is set inside the battery container, when the valve pops up, the high-pressure gas can be discharged directly from the front of the storm, thus avoiding the battery explosion.

Advantages of Battery Rupture Discs

- Improved security

The new energy vehicle’s rupture disk can prevent the battery from suddenly increasing pressure, bursting, or being subjected to external shocks, etc. And reduce battery damage and the impact on personal property.

- Reduced battery maintenance costs

Since the battery rupture disk can dissipate the high pressure inside the battery in time, reducing the probability of explosion inside the battery, it can reduce the maintenance cost of the battery, thereby reducing the economic pressure on the car owner.

- Increased service life

The new energy vehicle rupture disk can prevent the battery from overvoltage, overload, and overtemperature during charging. Thereby improving the battery’s service life.

Insufficiency of Battery Rupture Disks

Although battery rupture disks have many advantages, with the increasing number of new energy vehicles and the gradual increase in the production cost of battery explosion-proof valves, there are more and more types of explosion-proof valves. It is difficult for battery manufacturers to find matching rupture disk manufacturers. It hinders the large-scale standardized production of power batteries, which could be more conducive to the cost reduction of power batteries. Even after passing the test, verifying its feasibility will take a long time. For vehicle manufacturers, it also increases the difficulty of matching and procurement.

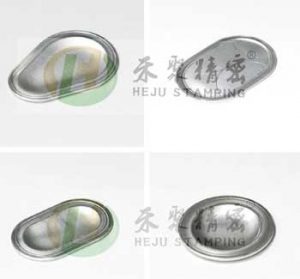

Heju Stamping-Your Bursting Discs Manufacturer for New Energy Vehicles

Heju Precision Electronic Technology Co., Ltd. is an precsion stamping manufacturer for electronic parts. Specializing in producing battery rupture discs for new energy vehicles. It is one of the earliest enterprises in China to develop and produce explosion-proof sheets. It has many models and comprehensive specifications. We have passed the three major certification systems of ISO9001, ISO14001, and IATF16949. Provide high-quality services for well-known customers at home and abroad, with a daily output of one million to meet your production capacity needs.