Press fit Terminal-Basic Characteristics and Assembly

The press fit terminal is an interface used to connect camera equipment. It is usually round, like a fisheye, called an eyelet terminal. It can realize the transmission of video signals and usually supports high-definition video transmission. Press-fit terminals are widely used in security monitoring systems, cameras, smart home equipment and other fields.

The Basic Structure of Press fit Terminals

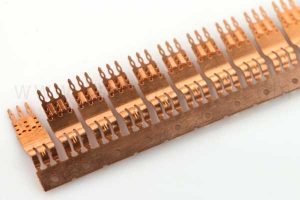

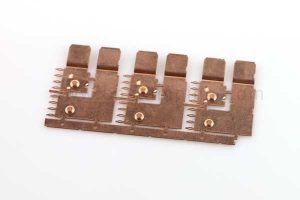

The press fit terminal pins consists of a root part, two elastic parts and a pin part. The elastic part is shaped like an arc line, and the two are arranged facing each other to form a fisheye hole. During installation, the elastic part is squeezed and elastically contracts, perfectly matching the conductive holes on the circuit board (PCB board).

Assembly Principle of Press fit Pins

The assembly of the press-fit pin is based on the elastic contraction of the elastic part when being squeezed so that the press-fit pin can be smoothly inserted into the conductive hole of the circuit board and cooperate with the conductive hole on the circuit board, thereby realizing the electrical connection between the press-fit terminal and the circuit board. As the contact area between the press-fit pin and the circuit board increases, the interaction force will increase, thereby reducing the contact resistance between the press-fit terminal and the circuit board and reducing the heat generated. Therefore, the press-fit terminal can be used in high-current situations.

Press fit Terminal Pins Connection

Combining eyelet terminals and PCB boards (i.e., circuit boards) is a solderless connection method. In addition, the crimp assembly method is more straightforward and can be removed and replaced. If the connector is damaged, It can be directly removed from the PCB and replaced with a new one.

As a connecting device, a press-fit terminal connects and contacts electronic products and circuit boards. Its manufacturing process also involves stamping technology. Stamping technology has significant advantages in the production of press fit terminals. First, the stamping process is simple and efficient and can quickly complete large-volume production tasks, improving production efficiency. Secondly, the continuity of the material is always maintained during the stamping process, making the surface of the press fit the terminal smoothly and flat without additional surface treatment, saving production costs. In addition, press-fit terminals of various shapes can be produced to meet the needs of different products and enhance product diversity and market competitiveness.

About Heju Stamping

Dongguan Heju Precision Electronic Technology Co., Ltd. is a manufacturer specializing in producing precision metal stamping parts. It has many years of experience in the production of press fit terminals. We have passed the three major certification systems: ISO9001, ISO14001, and IATF16949. It has a complete quality inspection system and electroplating. Supporting services can be actively customized to meet customer product needs!