Metal Stamping Rationalization Cost Reduction

The rationalization production of metal stamping is that reduce development cost, increase the material utilization, reduce material loss, and save processing time. The rationalization of stamping process is an effective way to reduce the cost of production.

A. In the process of stamping manufacturing, keeping continuous machinery operation can improve production speed.

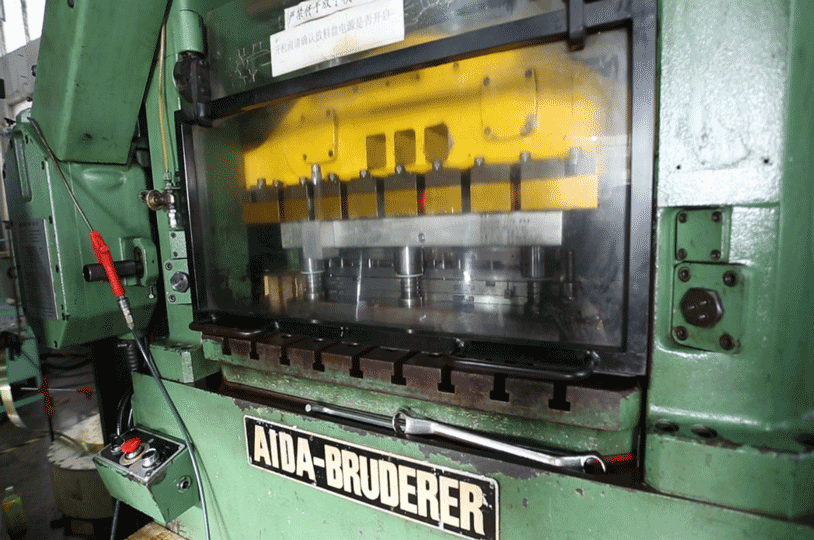

B. The stability of the press machine can ensure the stable performance in the process.

C. Improve safety operation consciousness; use the tools in the production process instead of manual operation.

D. Improve the mold performance, and reduce material wastage rate.

E. Strictly control the quality of the material according to customer drawings.

F. Strictly follow the technical standard SOP/SIP standard operating which can reduce scrap rate.

Heju stamping has been the forefront, of manufacturing high quality of Precision, Turned and Sheet stamping Metal Component form Brass, Copper, Aluminum, SUS. We also deal in various Ancillary Metal Components for Switchgear, Fuse gears, Miniature Circuit Breakers, Pumps, Telecommunication, Electrical and Automobiles.