Metal Rapid Prototype: The Ultimate FAQ Guide

1. What is Rapid Prototyping?

2. How to make a Metal Prototype?

3. Why need to use Prototype Samples?

4. What’s the Benefit for Prototype Parts?

5. Why it is important to make Prototype Stamping?

6. How Much is the Prototype Parts?

What is Rapid Prototyping?

Prototyping sample is made by product design or development phase in order to easily know if the product design meet cosmetic and functional requirements, and then evaluating the product based on the product drawings. The “rapid” nature of rapid prototyping means that the prototyping method is faster than creating traditional prototypes, and by setting direction for design team and repeating it quickly, a real value product can be created to customer or target consumer.

How to Make a Metal Prototype?

There are many methods to make metal prototype, which can be classified according to the production method and material properties.

1. According to production method can be divided into manual Metal prototype, CNC prototype and 3D printing prototypes.

1) Manual metal prototype: purely handmade;

2) CNC prototype: sample mainly finished by CNC machining production;

3) 3D printing prototypes: made by 3D printers;

2. According to material properties can be divided into plastic prototypes, silicone prototypes and metal prototypes and other prototypes, the most common are the following materials.

1) Plastic prototypes: raw material is plastic, mainly Plastic samples, such as TV sets, monitors, telephones, etc.. Like 3D printing the most common photosensitive resin is part of the plastic prototype category.

2) Silicone prototypes: raw material is silicone, mainly to show new product shape, such as cars, cell phones, toys, handicrafts, daily necessities and so on.

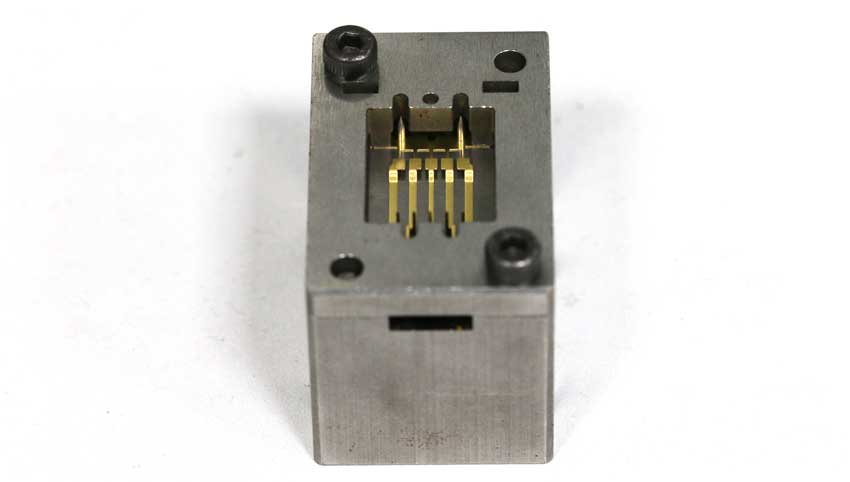

3) Metal prototypes: raw material like aluminum alloy and other metal materials, mainly for some high-grade products, such as laptop shells, engine models, cell phone shells, electronic components metal parts, handicrafts and so on.

[velocity type=”youtube” id=”qm7UysNDBsE” img=”https://www.cnstamping.com/wp-content/uploads/2021/12/metal-prototype-manufacturing.jpg” alt=”Play” color=”#FFFFFF” bkg_color=”#000000″]

Why Need to use Prototype Samples?

Industrial designers design a new product, will make prototype samples to check if product’s appearance and function is reasonable or not. The following points shows why need to use Prototype samples?

1) Verify appearance, just look at the design, cannot intuitive verify the product, what customer need is the physical product.

2) Verify function, according to the functional test cases, test item by item, check whether the product function meets user requirements.

3) Participate exhibitions, when there is no product, you can use the prototype sample instead of the product in the exhibition to get a good job preliminary publicity.

4) Direct sales, such as structural prototypes which also called functional prototypes can be sold directly on market. And see market response.

5) Reduce cost, product design is generally not perfect, or even unusable initially, if produce directly once there’s defects all will be scrapped, which is greatly waste manpower, material and time, the loss is much higher than prototype sample cost. As prototype sample normally with a small quantity, short production cycle, less manpower & material resources. Can quickly identify product design shortcomings and improve accordingly. Then providing sufficient basis for the product’s finalization.

What’s the Benefit for Prototype Parts?

Normally just developed or designed products are required to make prototype samples, which is the first step to verify product feasibility, and it is the direct & effective way to find out designing defects, deficiencies and drawbacks, until no deficiencies found from the individual prototype samples. Up to this point, also need to do a small batch trail production to see what to improve for mass production.

Product design is generally not perfect, or even unusable initially, if produce directly once there’s defects all will be scrapped, which is greatly waste manpower, material and time, the loss is much higher than prototype sample cost. As prototype sample normally with a small quantity, short production cycle, less manpower & material resources. Can quickly identify product design shortcomings and improve accordingly. Then providing sufficient basis for the product’s finalization.

Why it is important to make Prototype Stamping?

Many rapid prototyping processes produce parts that are at or near production quality, which can be very beneficial at many stages of the product design process.

Easier Identification for Design Concepts

Rapid prototyping allows prototyping companies to identify concepts beyond virtual visualization. This makes it easier to understand the design look and feel rather than simply making assumptions through a CAD product design, which helps to promote ideas and implement them in the design before they are *finalized*. In addition, rapid prototyping provides proof of this concept to *end customers who are seeking a more realistic product design rather than just viewing it on a computer screen.

Instant Change

With the physical model provided by rapid prototyping, changes can be incorporated immediately simply by receiving feedback from the customer. Several iterations are required before the design is completed. Each iteration process further improves the design, which helps build end-consumer confidence. This also helps to determine the actual needs of the market, making it possible to develop competitive products with better acceptance rates.

Save Time and Money

The cost of developing molds, models and specialized tooling can be high, but these costs can be eliminated through additive manufacturing. The same CAD software and presses can be used to create different geometries. Unlike traditional prototyping methods such as CNC machining, this process generates less scrap because rapid prototyping prints only the material needed to make the object.

Customizable Designs

One of the unique benefits of the rapid prototyping process is the ability to develop custom products. Better yet, it can be done on an individual basis. In addition, it does not require special tools or processes to make design changes in the product, and rapid prototyping makes it easier to try out multiple approaches and ideas. It further facilitates discussion through visuals, which leads to better, faster designs.

Reduce Design Flaws

The materials available for rapid prototyping are very similar to the actual product’s properties and durability, making them easy to test. The risk of failures and usability issues can be identified early to avoid possible future problems.

How Much is the Prototype Parts?

There are many factors that go into prototype cost, such as material, product structure’s complexity, product size, accuracy requirements, craft, surface treatment etc., as well as sample quantity, transportation costs and labor costs will all be considered in the cost. So generally engineer will make a reasonable price evaluation based on your drawings and product requirements.

The Best Prototype Metal Stamping Manufacturers in China

There are many famous metal prototype stamping companies in China, heju stamping is one of them. With more than thirty years of experience in prototype metal stamping manufacturing, Heju has more than 50+ experienced metal stamping engineering team, which is the first choice for global customers. If you are starting a metal prototype stamping project, contact heju today. With experience providing precision stamping solutions to 300+ reputable customers worldwide, we have the ability to be your prototype manufacturing partner and our experienced team is ready to get to work & creative.