Knowledge of Chip Packaging and Testing-Test Socket Pins Manufacturer

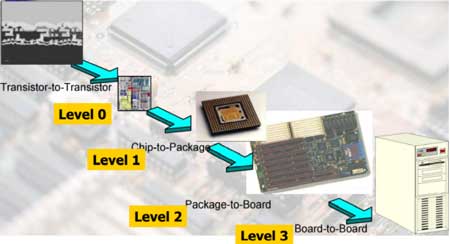

In the semiconductor industry, chip packaging and testing plays a vital role as a bridge between design and manufacturing. It not only affects the final performance of the chip but also directly affects the market competitiveness and cost-effectiveness of the product.

The Significance of Chip Packaging and Testing

Chip packaging and testing is the process of cutting the manufactured wafer into individual chips. And connecting the chips to external circuits through packaging technology while providing protection and support.

Packaging not only protects the fragile chip from the influence of the external environment but also realizes the electrical connection between the chip and the external circuit through pins, solder balls, etc.

Testing is an important step to verify whether the packaged chip meets the design specifications and performance requirements and ensures product quality.

The Core Process of Chip Packaging and Testing

Packaging Test

Packaging test is the last step of chip packaging and testing, and it is also an important link to ensure product quality.

Functional Test

The functional test assesses whether the packaged chip can perform the various functions specified in the design specifications. During the testing process, specific test vectors are input into the chip. And the output response is monitored to determine if it meets the expected results.

Functional tests usually include two forms: static test and dynamic test. The static test mainly verifies the electrical characteristics of the chip in the static state. The dynamic test simulates the signal changes in the actual working scene to verify the dynamic performance of the chip.

Performance Testing

Performance testing is the process of testing and evaluating various performance indicators of the chip. Performance testing includes speed testing, power consumption testing, noise testing and other aspects.

Speed testing mainly verifies the processing speed and response time of the chip; power consumption testing evaluates the energy consumption of the chip in the working state; noise testing detects noise signals such as electromagnetic interference generated by the chip during operation.

Reliability Testing

Reliability testing is the process of evaluating the stability and reliability of the chip during long-term use. Reliability testing includes temperature cycle testing, humidity testing, vibration testing and other aspects.

Temperature cycle testing simulates the working conditions of the chip under different temperature environments. Humidity testing evaluates the corrosion resistance of the chip in a humid environment; vibration testing simulates the vibration and shock that the chip may encounter during transportation and use.

Through reliability testing, it can be ensured that the chip can maintain stable performance in various harsh environments.

By simulating various environments and stress conditions of the chip during long-term use, people can evaluate its reliability and life. In this process, the spring plays a vital role as a link between the test fixture and the chip. During the test, the stability and conductivity of the spring directly affect the accuracy and reliability of the test data.

When testing a chip, it is essential to select an appropriate spring contact terminals to guarantee the effectiveness and reliability of the assessment. The contacts terminals establishes conductive contact, allowing for the acquisition of the chip’s operational data. It is crucial for determining whether the product’s performance is normal. Additionally, it should take care to protect the chip test socket pins from excessive mechanical and thermal stress during both installation and use. This precaution helps prevent damage to its structure and performance. Thereby ensuring the proper functioning of the test fixture and the accuracy of the test results.

Chip Test Socket Pins/Terminals Design

- Design

The design of the contacts terminals needs to be customized according to factors such as the size, shape and test requirements of the chip. For example, for the terminals in the laser chip aging test fixture, its design needs to consider how to provide sufficient installation space for the laser chip and avoid damage to the chip during operation.

- Structure

The contacts terminals usually has a mounting piece and an elastic bend. The mounting piece is used to fix the shrapnel on the test fixture, while the elastic bend is used to contact the chip and apply appropriate pressure. The end of the elastic bend may also be provided with a positioning head and other structures to ensure the accurate positioning of the chip during the test.

To ensure the product’s reliability, it is essential to minimize early failures. Potential defects in semiconductors can be identified through various media. When voltage stress and heating are applied to the device, the terminal begins to function. Highlighting any potential defects within the chip during operation. The quality of the contacts terminals is critical for packaging and testing companies. As it directly impacts the accuracy of the chip parameters during these processes.

Hejustamping-Chip Test Socket Pins Stamping Manufacturer

Dongguan Heju Precision Electronic Technology Co., Ltd. is a manufacturer specializing in the production of test sockets pins in semiconductor industry. Such as chip package and test sockets, burn-in test sockets, etc. It can provide corresponding solutions according to the different needs of customers. The contact terminals has many specifications and a long life, which can meet your testing requirements. In terms of absolute accuracy and repeatability of the product, it can achieve rapid prototyping of any complex folding structure!