Knowledge About Progressive Die Stamping

What is Progressive Die Stamping?

Progressive Die Stamping is a unique metal forming process to cut raw metal sheets to develop parts.

This metal stamping comprises several workstations, each of which accomplishes different procedures. Each step is built on the previous step till the preferred form is attained. All these actions have the same standard configuration with some possible variations.

Key Benefits of Progressive Stamping

- Minimal Scrap

For creating the final part, progressive die metal stamping includes different forming procedures like punching, coining, bending, etc. The scrap produced significantly less as a substantial amount of material is utilized. This makes it one of the most cost-effective materials for component manufacturers.

- Quick Production & Cost Save

The progressive die design process utilizes constant product feed via different die stations. Compared with conventional machining, this permits you to produce more parts in a much shorter period. With this stamping procedure, you obtain the most affordable cycle time per part for high-volume components.

- Short Setup Times

The progressive stamping process takes much less time than standard stamping methods. To create complicated parts, it needs multiple arrangements, device adjustments and die modifications in traditional stamping, whereas we can achive the same in one stamping die operation.

- Complex Geometrics

The building nature of the die stations in a progressive stamping tool allows you to create more intricate geometrics. Also, people can accomplish all the needed geometrics of a component in a single procedure of progressive die.

Applications of Progressive Stamping Tool

Progressive die metal stamping deals a reliable and cost-efficient method for creating parts in huge quantities, making it a terrific choice for industrial applications such as:

Medical

Agriculture

Appliances

Electronics

Automotive

Aerospace

Progressive Stamping Process

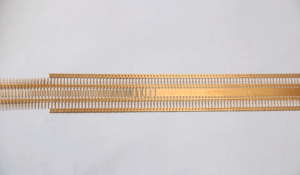

Progressive Stamping uses a type of tooling called a progressive die, which has numerous stamping stations to perform simultaneous procedures on a sheet metal strip. Initially, a trained worker fits the die into the stamping press.The technician triggers the equipment as soon as finishing the proper adjustment. While the die is open, the metal moves through the die, being exactly fed into the die with each press stroke. When the die closes, it works with the metal, including coining, bending, cutting, embossing, and more. Once the metal has moved through each station, the finished part is ejected from the die.

Progressive Die Stamping vs Transfer Die Stamping

Actually,Progressive tool stamping resembles Transfer Press Stamping with some distinctions in the working nature.

Progressive die stamping is designed for high-quantity manufacturing of smaller parts, commonly surpassing 50,000 items annually. While transfer Die Stamping is also suitable for high-quantity production, it differs because the component is separated from the metal strip during the first procedure. It is usually utilized for creating significant components like tube applications, frames, coverings, and structural components.

Progressive Stamping Die Services from Heju

We offer custom precision and micro-stamped parts and progressive die tool manufacturing. With thirty years of experience, Our creative team of engineers takes care of every piece of information to ensure you get the best quality parts in a minimal time. To learn more, visit our capacities and tooling pages or call us to start.