How to Distinguish the Male and Female Auto Wire Terminals?

The connector has four elements: contact interface, contact coating, contact elastic element, and plastic connector body. Except for the plastic body, the wire terminals determine the other three elements. The wire terminal is the core of electrical connection and signal transmission. In terms of mechanical properties, There are high requirements in terms of electrical performance and anti-vibration performance. It plays a decisive role in the performance of automotive connectors. There are also a certain number of holes in the car so that the terminals can insert into the corresponding holes and fixed by the fixing frame.

The connector has four elements: contact interface, contact coating, contact elastic element, and plastic connector body. Except for the plastic body, the wire terminals determine the other three elements. The wire terminal is the core of electrical connection and signal transmission. In terms of mechanical properties, There are high requirements in terms of electrical performance and anti-vibration performance. It plays a decisive role in the performance of automotive connectors. There are also a certain number of holes in the car so that the terminals can insert into the corresponding holes and fixed by the fixing frame.

Difference Between Male and Female Wire Terminals

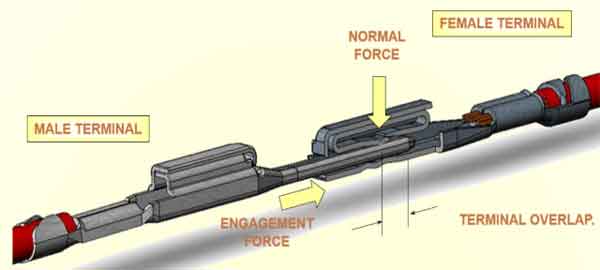

Connector terminals are divided into functional areas, which can be divided into the crimping area, transition area, self-locking area, and bonding area. Among them, The bonding area is where the male and female terminals are mated, the position where the terminal engagement system is located.

The side of the plug (protruding connector) is male, and the side of the jack (recessed connector) is female. Its appearance and shape distinguish it. The protruding head is a male terminal, and the head with a hole is a female terminal.

Male Crimp Terminals

The shape of the crimp terminal in the male connector is cylindrical (round pin), square column (square pin), or flat (insert).

Female Crimp Terminals

The inner crimp terminal contact of the female connector is a jack. There are many types and structures of the hole, such as cylindrical type (splitting, shrinking), tuning fork type, cantilever beam type (longitudinal slotting), folding type (longitudinal slotting, 9-shaped), Box-shaped (square jack) and hyperboloid wire spring jack, etc.

The Function of Wire Crimp Terminals

In layperson’s terms, the function of the female end is to receive and accept the terminal wires of the male end. In addition, there are one or more protrusions insert into other components. People usually call this type of terminal wire as a male end. And they call the receiving or notched one as a female end if it is reversed when the current flows from one device to another. The role of the connector’s male and female seats is to enhance safety or ensure the normal operation of the device, preventing some unsafe factors from occurring or improper connections.

With the increase in car functions and the widespread application of electronic control technology, there will be more and more electrical components and wires. The car’s circuits and power consumption will increase significantly, and the wiring harness will become thicker and heavier. How to arrange many wiring harnesses more effectively and rationally in the limited car space so that the new energy wiring harness can play a greater role? That is a big problem that car manufacturers need to solve.

With the advent of the new energy era, only the continuous exploration of the manufacturing technology of parts can satisfy the rapid iteration of new functions. Connector Stamping terminals will be smaller in size, higher in precision, and stronger in current carrying capacity in the future. Their terminal structures will also undergo new technological changes and developments. It can better meet the actual needs of the car!

Why Choose Us for Your Automotive Wire Terminals Supplier?

Heju Precision Electronic Technology Co., Ltd. is a precision stamping manufacturer specializing in producing and designing automotive terminals. It has passed the three major certification systems of ISO9001, ISO14001, and IATF16949. Besides, It has many years of experience in connector terminal design and development. The thermal conductivity and electrical conductivity of the terminal are stable. We can meet the imported brands quality standards nnd actively cooperate with customer product needs to achieve localization substitution!