How Press Fit Terminals Revolutionize Electrical Connectivity

In the fast-evolving world of electrical engineering, press-fit terminals (also known as press-fit pins) have emerged as a cornerstone for reliable, high-performance connections. Designed for seamless integration and durability, press-fit connector terminals and press-fit pins are transforming industries ranging from automotive systems to consumer electronics. Let’s explore why these components are critical to modern connectivity solutions.

What are Press-fit Terminals?

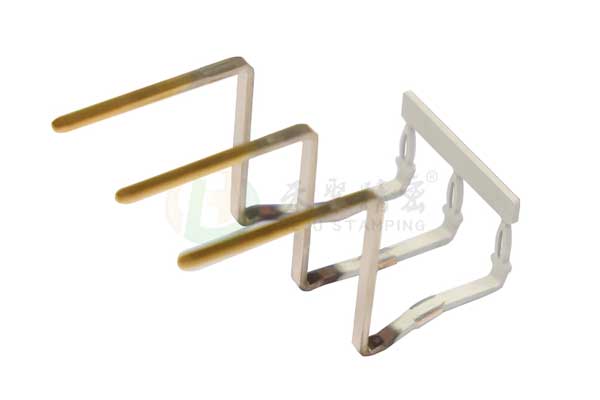

Press-fit terminals are specialized connectors that create secure electrical joints without soldering. Their unique “press fit” design features a hollow, eye-shaped contact that allows them to be pressed directly into printed circuit boards (PCBs) or other substrates. This innovative structure ensures a gas-tight connection, minimizing resistance and enhancing long-term reliability.

Key Benefits of Press Fit Connector Pins

- Solderless Installation: Unlike traditional soldered joints, press fit pins eliminate thermal stress and reduce assembly time, making them ideal for high-volume production.

- Superior Conductivity: The press-fit design maintains consistent contact pressure, ensuring low electrical resistance and stable signal transmission.

- Vibration and Shock Resistance: Engineered to withstand harsh environments, press fit connectors excel in automotive and industrial applications.

- Cost Efficiency: Reduced labor and material costs, coupled with minimal maintenance, make them a cost-effective solution.

Applications of Press Fit Terminals/Pins

From automotive control units to smart home devices, press fit pins are versatile and widely used:

- Automotive Electronics: Powering ECUs, sensors, and infotainment systems with vibration-resistant connections.

- Industrial Machinery: Ensuring robust connectivity in motor drives, robotics, and power distribution systems.

- Consumer Electronics: Enabling compact, reliable designs for smartphones, laptops, and IoT devices.

Why Choose Press-fit Connectors?

The rise of miniaturization and high-speed data transfer demands connectors that balance precision and durability. Press-fit connector terminals address these needs with the following:

- High-Density Layouts: Their compact size supports PCB designs with limited space.

- Temperature Resilience: Operate reliably in temperatures from -40°C to 125°C.

- Customization: Available in various sizes and materials (e.g., brass, phosphor bronze) to meet specific application requirements.

The Future of Press Fit Technology

As industries push for more innovative, lighter, and more efficient devices, pressfit terminals are evolving to meet next-gen challenges. Innovations like gold-plated contacts for enhanced corrosion resistance and automated press-fit systems are setting new standards. For engineers and manufacturers, adopting press fit connectors means staying ahead in a competitive market.

Conclusion

Press-fit Terminals are more than just connectors—they are enablers of innovation. By combining solderless efficiency, unmatched durability, and adaptability, they empower industries to build safer, faster, and more reliable systems. Whether you’re designing automotive controls or cutting-edge electronics, press fit pins and press fit connectors deliver the precision your projects demand.