How Can the EV Prismatic Battery Safety Vents Blasting?

What is EV Prismatic Power Battery Safety Vent?

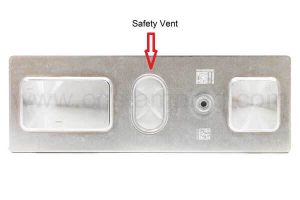

The EV prismatic lithium battery safety vents are a device that prevents blasting caused by overpressure of gas inside the battery. During battery charging or use, the battery will produce a large amount of gas for various reasons, such as overcharging, short circuit or excessive temperature. If these gases cannot be discharged in time, the gas pressure inside the battery will increase, eventually leading to the battery exploding.

Structure of Prismatic Lithium Battery Packs

EV Prismatic lithium battery packs are usually composed of multiple prismatic battery cells. They are used to store and release large amounts of electrical energy. Since the power battery pack stores a lot of energy, once an abnormal situation occurs (such as overcharging, over-discharging, high temperature, etc.), it may cause gas generation and pressure increase in the battery pack, and even cause fire or explosion in severe cases.

To ensure the safety of the battery pack, each power battery is usually equipped with a battery safety vent. The safety vent is a device that can control the battery’s internal pressure and release overpressure or abnormal pressure in time to reduce the risk of explosion or fire.

Blasting Principle of EV Battery Safety Vents

The main explosion principle of the EV battery safety vent is based on the thermal expansion characteristics and pressure difference. When the gas pressure inside the battery exceeds the safety value set by the safety vent, the valve will explode, and a part of the gas will be discharged through the valve, thereby reducing the pressure of the gas inside the battery and maintaining the safe working condition of the battery.

When the gas pressure inside the battery rises above the safety pressure set by the valve, the pressure difference causes the valve to be acted upon by force, breaking through the limits of the safety vent, bursting open the valve, and discharging the gas inside the battery.

Explosion Parameters of EV Battery Vents

The explosion parameters of the EV prismatic battery vents are determined according to the battery’s design and use requirements. In addition, the opening strength of the battery safety vent also needs to be reasonably controlled. If it is too large or too small, it will affect the working effect of the valve.

Explosion Process of EV Battery Venting Valves

The explosion process of the EV battery venting valves mainly includes two stages: pressure accumulation and explosion release. During the pressure accumulation stage, the gas pressure inside the battery gradually increases. After reaching the threshold, the safety vent explodes rapidly due to the pressure. The valve is fully opened and enters the explosion release stage. The gas inside the battery is quickly discharged through the valve, thereby maintaining the safe working state of the battery.

Tips to Choose Suitable Safety Vents for Prismatic Lithium Batteries

Purchasers of EV battery safety vents for prismatic power batteries should pay attention to the fact that the safety vent must meet the following requirements during the blasting process:

- First, fast response speed. That is, it can explode in time before the internal gas pressure of the battery reaches a dangerous value.

- The second is reliable working performance. That is, it can work under different environmental conditions and is not affected by external factors.

- The third is long-lasting service life, ensuring long-term stable operation and avoiding frequent replacement.

About Hejustamping-Prismatic Battery Safety Vents Manufacturer

Dongguan Heju Precision Electronic Technology Co., Ltd. is a company specializing in the production of battery safety vents for new energy vehicles. It is one of the earliest companies in China to develop and produce EV battery venting valves. It has many models, comprehensive specifications, and a single unit pressure range of up to 0.03MPA. CPK>2.0. It can cooperate with customers in developing new products and has passed the three major certification systems: ISO9001, ISO14001 and IATF16949.