Electric Vehicle Busbars Manufacturer

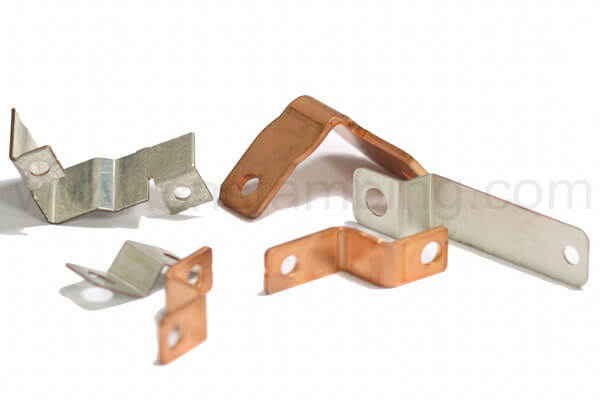

The busbar is a part of conducting electrical current through the major electrical pathways of an EV’s various systems and sub-systems. It is also called bus bars or buss bars, they are often metallic strips of copper, brass, or aluminum that both ground and conduct electricity.

Hejustamping ensures your power distribution system operates dependably and safety with high-quality bus bars. We are an professional metal stamping supplier of kinds of bus bars, such as lithium battery busbars, tinned copper busbars, busbar in battery pack; Specializing in high-performing busbars for demanding environments.

Latest Stamped EV Busbars Projects

New energy vehicle busbars have high mechanical properties, good electrical and thermal conductivity, excellent corrosion resistance, beautiful metallic luster during electroplating and brazing, and good forming and processing properties.

Best Lithium Battery Bus Bars Performance

Like all electric circuits, busbars require protection against the effects of short-circuit currents. Any kind of openings boost the risk of debris accumulation in air spaces and the opportunity of succeeding damage increases as a result of high normal operating currents and the quantity of energy offered.

We combine 3D modeling and tool simulation with the best tools to provide our customers with tailor-made busbars that fit correctly and perform optimally at a competitive cost. With more than 30 years of expertise and experience in die and metal stamping, we can achieve better performance than other stamping parts in our industry. Our services include:

- Progressive Dies High Speed Stamping

- Tool and Die Design and Manufacturing

- Rapid Prototyping

- PG/WE Waterjet cutting

Why us for your Automotive Power Distribution Unit Busbars Project?

Heju Stamping is a professional OEM stamping manufacturer of produing busbars in electric vehicle industry. With 30yrs experienced engineer teams, we can provide expert, hands-on advice regarding manufacturing. We can assist customer to select the proper material, dimensions, tolerances, and optimal performance with the best cost solutions.

Equipped with in-house tooling rooms, Heju Stamping can design and build progressive stamping dies to produce customized electric vehicle busbars solutions that enable tight tolerance specifications for busbar performance and automatic assembly needs. performance with the best cost solutions.

Our Stamping Capabilities

Service

Equipped with more than 40 sets of high-speed imported punching machines (30T-160T) and dies processing equipment, which ensures production runs most efficiently and parts are 100% quality assured. We offer a full suite of metal stamping, metal forming, tooling and assembly services.

From sample testing to mass production to delivery, we monitor product quality throughout the process to ensure that each product meets the high standards of our customers.

The company currently has over 230 employees, of which R&D designers and mold technicians account for nearly 50%. The internal mentoring system as the core of the personnel training system, gathered many senior engineers and mold technicians, which has created an excellent team of stamping craftsmen in China.

Precision Metal Stampings

Other Production Parts

Hejustamping is a professional manufacturer who is focus on providing electronic components stamping solutions to global customers.

We produce stamping components include wire and cable connectors terminals, battery safety vents, stamped electrical terminals, press-fit terminals/pins, busbars, electrical spring contacts, micro deep drawn parts, electronic shielding components, lead frames, assemblies and more.

Widely used in new energy vehicle wiring harnesses and lithium battery, medical devices, consumables, chip packaging & testing, sensors and other fields.

The daily production capacity reaches millions units, with highly customized production capabilities to meet the special requirements of different customers.

© Copyright 2012 - 2023 CNstamping All rights reserved.