Detailed Explanation of the Use of Mini-Fakra Terminals

The components are closely connected to ensure accurate and efficient transmission of information. Among them, Mini-Fakra terminals and Fakra terminals are the best among automotive coaxial connectors. They are widely used in the connection of key components such as antennas, GPS, radios, Bluetooth and in-car entertainment systems. This article will explore the specific uses of Mini-Fakra terminals and compare the differences between Fakra terminals in many aspects.

Uses of Mini-Fakra Terminals

Mini-Fakra terminals are a miniaturized version of the Fakra series connectors. It plays an important role in modern automotive electronic systems due to their small size, excellent performance and good environmental adaptability. Their main uses are reflected in the following aspects:

- Antenna connection

As the trend of automotive intelligence and connectivity continues to accelerate, the role of antennas as a vital link for vehicle communication with the outside world is becoming increasingly important. Thanks to their compact design, Mini-Fakra terminals can be seamlessly integrated into the roof, rear window. And even bumper lights, facilitating reliable connections for multiple antennas such as GPS, FM/AM broadcasting, satellite communications, and mobile internet. This integration ensures stable and clear signal transmission.

- In-car entertainment system

In the in-car entertainment system, the Mini-Fakra terminal is not only used to connect audio and video signal sources, such as players, Bluetooth modules, and USB interface lights but also plays an important role in data transmission. It supports high-speed data transmission. And allowing high-quality media content such as high-definition video and lossless audio to be played smoothly. It is greatly improve the entertainment experience of drivers and passengers.

- Communication module integration

With the development of Internet of Vehicles technology, vehicles need to communicate with the outside world more frequently and complexly. Mini-Fakra terminals are widely used in vehicle communication modules. Such as vehicle WIFI, telematics, etc., due to their excellent electrical performance and reliable mechanical structure to ensure that vehicles can receive and process commands and data from the network in real time.

- Sensor interface

In autonomous driving and advanced driver assistance systems (ADAS), various sensors, such as radar, camera, lidar, etc., are indispensable components. Mini-Fakra terminals serve as a bridge between these sensors and the central processing unit. Their high reliability and low loss characteristics ensure the accurate transmission of sensor data. And providing a strong guarantee for the safe driving of vehicles.

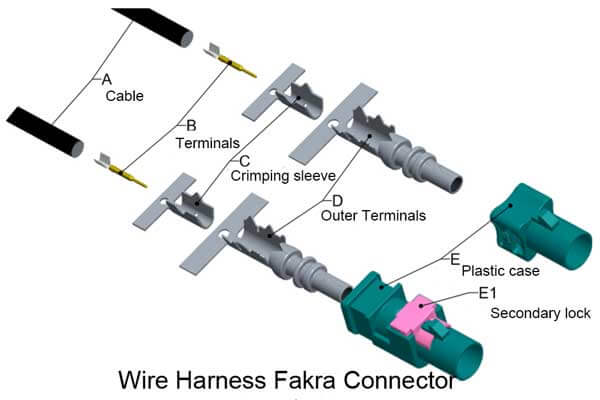

Differences From Fakra terminals

Although Mini-Fakra terminals and Fakra terminals have many similarities in function and application, there are still significant differences between the two in many aspects, mainly reflected in the following aspects:

- Size and weight

The most intuitive difference is size and weight. Mini-Fakra terminals are smaller and lighter than Fakra terminals. This feature makes Mini-Fakra terminals more advantageous in space-constrained situations. Such as small vehicles, and can be more flexibly arranged throughout the vehicle body. It also helps to reduce the weight of the vehicle and improve energy efficiency.

- Frequency range and bandwidth

In terms of electrical performance, Mini-Fakra terminals generally support higher frequency ranges and higher bandwidths. This means that it can transmit higher-quality data and signals, meeting the needs of modern automotive electronic systems for high-speed and large-capacity data transmission. In contrast, although Fakar terminals can also meet most application scenarios, they may need to be more in scenarios that pursue extreme performance.

- Different application scenarios

Due to the differences in size and performance, the application scenarios of Mini-Fakra terminals and Fakra terminals are also different. Mini-Fakra terminals are more suitable for occasions with strict space requirements and high data transmission quality requirements. Such as high-end models, autonomous driving vehicles, etc.

However, because automotive connectors involve life safety issues, it is only possible for manufacturers with a certain scale to sell them. And from stamping/assembly/testing, they must comply with the IATF16949 specification. It is difficult for small factories to implement relevant requirements, so it is urgent to form a complete interactive model. Suppliers are required to have the ability to respond quickly and change engineering during the entire development and even mass production process. However, with the rapid rise of the new energy vehicle market, some companies in the FAKRA and Mini-Fakra connector markets cannot meet customer needs due to their technical level and delivery capabilities. Because terminal parts are no longer simply connecting devices but higher-level components that integrate devices and control systems.

Hejustamping-Automotive Wire Connector Terminals Stamping Manufacturer

Dongguan Heju Precision Electronic Technology Co., Ltd. is a renowned manufacturer that specializes in the production and design of automotive wire connector terminals. In 2016, it obtained the IATF16949 system certification. The company is equipped to produce terminals for popular car models such as BMW, Wenjie, Xiaopeng, and Geely. The Mini-Fakra and Fakra terminals manufactured by the company demonstrate stable signal transmission and meet the quality standards of imported brands. With a complete support service and quality inspection system, as well as 39 imported punching machines ensuring high-efficiency production and strong delivery capabilities, we can proactively customize products to meet customer needs and contribute to domestic production.