Depth Analysis of Press-fit Terminals Technology and Application Advantages

In recent years, press-fit terminals technology has been increasingly used in the manufacture of electrical systems in the automotive, energy and other markets. What is Press-Fit technology? What are its application advantages?

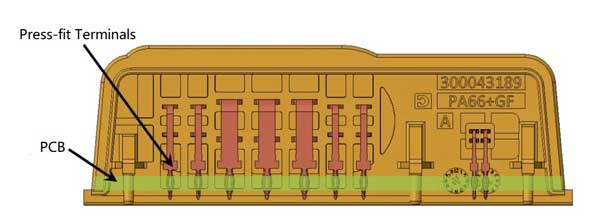

Technical Introduction of Press-fit Terminals

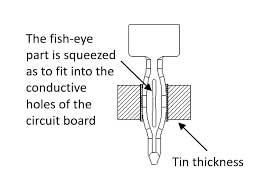

Press-Fit, commonly referred to as “press-fit terminal,” serves as an alternative to traditional soldering methods. It primarily ensures a reliable connection of electrical contacts through cold connection techniques that do not require solder. The press-fit end is inserted into the PCB hole, achieving a strong clamping force with a relatively small pressing force. During this pressing process, the press-fit end undergoes elastic deformation, establishing a tight connection characterized by low contact impedance and high reliability.

Simply put, press-fit pcb pins create a solderless electromechanical interconnection. It allows the connector to be quickly installed on the PCB module. The elimination of the soldering process not only reduces the connection impedance but also further reduces production costs and assembly time.

Application Advantage

- Simplify the Assembly Process and Improve Production Efficiency

- No need for welding: The press fitterminal pin is connected by crimping. And no welding operation is required, thus eliminating the tedious steps of preparation, heating, cleaning and inspection required for welding.

- Quick installation: Since no welding is required, the installation speed of the press-fit terminal is greatly accelerated. It helps to shorten the product assembly cycle and improve production efficiency.

- Improve the Quality and Reliability of Connection

- No thermal stress: In the traditional welding process, PCB and components may be deformed or damaged due to thermal stress. The press-fit pin adopts crimping to avoid the generation of thermal stress, thereby improving the reliability of the connection.

- Tight connection: small insertion force, high clamping force. The press fit terminal will produce elastic deformation during the crimping process. An providing low contact impedance and high reliability of the tight connection. This tight connection helps to reduce signal attenuation and interference and improve signal integrity.

- Avoid welding defects: In the traditional welding process, welding defects such as solder accumulation, cold welding, rosin welding, and solder bridge may occur. The press-fitterminal/pin has no solder bridging, no flux residue, and no need for cleaning. Which, to a certain extent, avoids problems caused by welding, such as cracking and non-wetting.

- Reduce Production and Maintenance Costs

- Reduce material costs: Compliant pins do not require the use of welding materials such as solder and flux, thereby reducing material costs.

- Simplify maintenance: Since compliant pins have stable connections and are easy to maintain, the module replacement and repair process can be simplified, reducing maintenance costs.

Processing method of Press Fit Compliant Pins

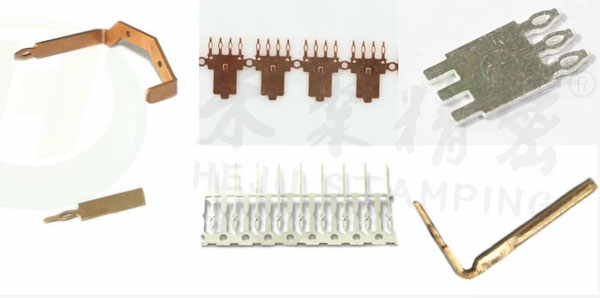

Press fit compliant pins are a type of connection device used for the connection and contact of electronic products and circuit boards. Stamping technology is commonly used in their manufacturing process. This is because stamping technology has great advantages in the production of compliant pins. First, the stamping process is simple and efficient and can quickly complete large-scale production tasks, thereby improving production efficiency. Second, the continuity of the material is always maintained during the stamping process, making the surface of the compliant press-fit pins smooth and flat without the need for additional surface treatment. Thus saving production costs. In addition, the production of press fit terminals in various shapes can be achieved to meet the needs of different products, thereby improving product diversity and market competitiveness.

Hejustamping-Unique Press-fit Terminal Technology Manufacturer

Dongguan Heju Precision Electronic Technology Co., Ltd. is a manufacturer specializing in precision metal stamping parts. With many years of experience in producing press-fit terminals, the company has successfully passed the three major certification systems: ISO9001, ISO14001, and IATF16949. It boasts a comprehensive quality inspection system and offers electroplating support services. Additionally, the company is committed to collaborating with customers to meet their product customization needs!