MICRO & PRECISION DEEP DRAWING STAMPING

What is Deep Drawing Stamping?

Deep drawing stamping is a machining process that process a flat blanking strip with a certain shape obtained after punching into various open hollow parts or reduces the diameter of the open hollow parts and increases the height. The deep drawing process can be used to manufacture cylindrical, stepped, tapered, spherical, box-shaped and other irregularly shaped thin-walled parts.

Deep Draw Manufacturing Benefit

To compared to the methods which made metal and alloys into definite shapes, deep drawing process with more cost-effectiveness in raw material and equipment. In addition, deep drawing forming can make the best metal products, such as parts for automobile mufflers, fine parts for large machines, and smaller parts for metal structures.

Micro Deep Drawing Characteristics:

- Max. Deep Drawing Height: 30mm

- Max. Sheet Thickness Within 1.0mm

- Diameter Ranges From 2.0mm to 50mm

- High Precision: +/-0.01mm

- R/T<0.5

Small Deep Drawn Parts We Customized:

- Deep Drawing Metal

- Deep Drawing Stainless Steel

- Deep Drawing Aluminum

- Copper/Brass Deep Drawing

- Deep Drawing Steel

- Deep Drawing Titanium

Heju stamping focus on customized small deep drawn parts & micro deep draw metal stamping service. Products mainly used in the automotive, medical, tele communications, consumer electronics and other industries.

We have 36 sets of high-speed punch press ranging from 30-160T, which can fully meet the short-term/long-term, large-volume, and complex product requirements. We have IATF16949&ISO9001 certificate, can provide you comprehensive support from product design to mass production. Strictly control dimensional tolerances, ensure product consistency, and meet your needs.

We are a well-known micro deep draw and precision stamping manufacturer in China, with business all over the world, cooperated with Dyson, Amphenol Fci, Titan etc.

Deep Drawn Components Attention:

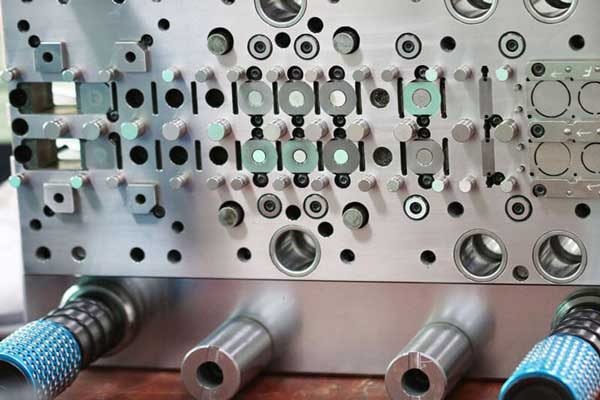

Deep Draw Dies VS Stamping Toolings

Generally speaking, deep draw tooling belongs to progressive toolings. Stamping die include blanking die, bending die, forming die and deep draw progressive die. The biggest difference between deep drawing die and forming die is raw material deformation method. Bending die deformation caused by the single stress of bending action, but deep drawing tooling probably by three-way stress. Small deep drawn part maybe formed by one or two times deep drawing process. So can make a composed tooling which with blanking, deep drawn and form with blanking die.

Application of Deep Drawing Stamping and Formed Parts

- Medical Device Cover

- Vaccine Packaging Lid

- Automotive Components

- Motor Shield & Parts

- Deep Drawn Aluminum Cans

- Deep Drawn Enclosures

- Deep Drawing Cup

- Shielding Case

- Electronic Motor, Micro Motor

- Perfume Cover

- Electronic Accessory Shield

- Pacemaker Enclosure

Related Cases Studies

Get A Quote For Your Next Projects

No matter your project is complicated or simple, our deep drawing experts will provide a solution, you will get an accurate quotation within 12 hours.

© Copyright 2012 - 2023 CNstamping All rights reserved.