6 Methods of Improving the Service Life of Stamping Dies

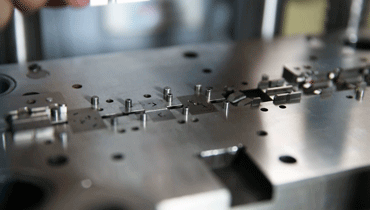

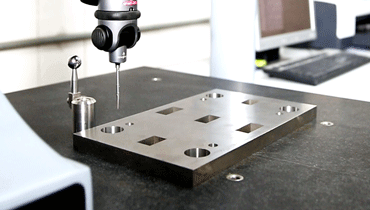

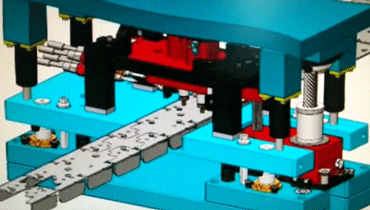

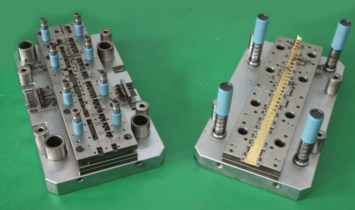

1 Improved Design of Stamping Die Stamping die life time is based on rational design.In stamping die design, engineers should give full consideration to form of mold,fixing method and guide form of concave convex die,determination of the pressure center and rigidity of lower plate.Especially for blanking die, gap value has a great influence on the