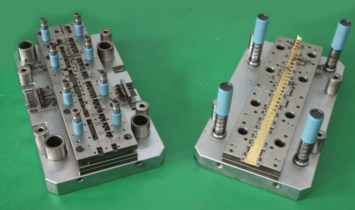

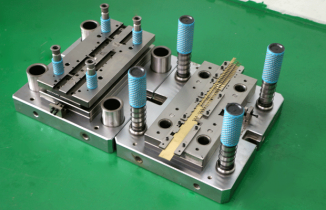

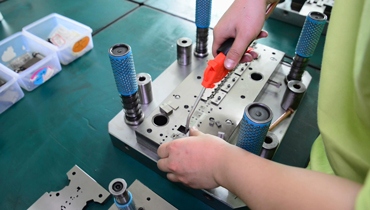

How to Maintain Metal Stamping Die

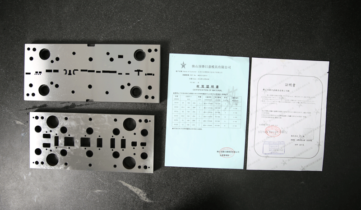

Nowadays, metal stamping parts are widely used in daily life products. The demand of stamping die from manufacturers is also increasing. Therefore, stamping die daily maintenance is very important. If we can maintain the stamping die regularly, the stamping die life time will be increased. 3 Levels of Metal Stamping Die Maintenance: level 1,