Deep Draw Stamping: The Ultimate FAQ Guide

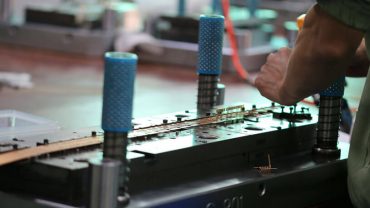

What is Deep Draw Stamping? Deep Draw Metal Stamping is a processing method for making open hollow parts from flat material or hollow process parts by using a deep drawing die under the pressure of press. Cylindrical deep drawn aluminum cans are typical deep drawing applications. What are the Types of Deep Drawing Processing?