Battery Cover Plate on New Energy Vehicles-Rupture Discs Manufacturer

In the wave of new energy industry development, the battery plays a pivotal role. It is the car’s heart and the vehicle’s source of power. According to different battery packaging technologies, there are three types batteries: cylindrical, prismatic, and pouch cells. The corresponding lithium battery structural parts are cylindrical structural parts, square structural parts, and aluminum-plastic film. Among them, the cylindrical and square structural parts are also called hard shell structural parts, composed of a shell and a cover plate.

Structure of Prismatic Battery

Taking the prismatic battery as an example, the components are mainly five parts: battery cover, positive and negative electrodes, insulating film, electrolyte, and battery case. The top cover and the shell form a sealed whole through laser welding.

There are many welding processes for the top cover of the prismatic battery, and its structure is mainly composed of the top cover plate, positive and negative poles, explosion-proof devices, etc. Various parts are assembled to form the battery cover plate, and the cover plate and the outer shell form a complete battery part.

Main Components and Functions of Battery Cover Plate

Top Cover and Sealing Ring

The function is sealing. The top cover and the aluminum shell are laser welded to wrap and fix the bare cell and realize the sealing effect, which protects the internal materials of the lithium-ion battery from damage and has a specific structural strength;

Pole and Adapter Piece

The function is current conduction. In the battery, the top cover pole, the adapter piece, and the battery tab are welded and conducted to ensure the charge and discharge of the battery cell; In the module, the top cover pole and the bus bar are laser welded and bolted connected to form a series/parallel connection;

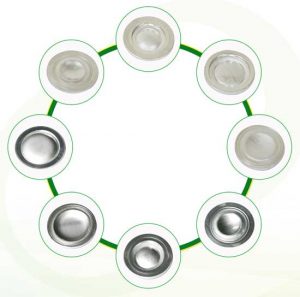

Battey Rupture Discs

The function is relief pressure. When the internal pressure increases to a certain level, the top cover explosion-proof valve will open for pressure relief;

Flip Plate

The function is fuse protection. In the ternary battery, when the internal air pressure increases to a particular value, the top cover flip sheet lifts and contacts the negative riveting block so that the positive and negative electrodes of the top cover are directly short-circuited and at the same time, the aluminum connecting piece is fused to cut off the current quickly.

Plastic Coating

The function is reduce electrical corrosion. The plastic on the positive pole is made of conductive PPS, which reduces the potential difference between the positive pole and the aluminum shell, prevents electric corrosion of the top aluminum shell, and thus improves product quality and service life; the plastic on the negative pole uses insulating PPS.

In Conclusion

Among the hard-shell structural parts, the cover plate has a variety of functions. In contrast, the battery rupture discs and the flip plate are the main safety components. And the sensitivity index is strictly required. The cover plate has functions such as current conduction, pressure relief, fuse protection, and reduction of electrical corrosion. The material is changed from stainless steel to copper-aluminum composite material. The rupture disk is designed to play a major role in battery safety protection. When the internal pressure exceeds the opening pressure of the explosion-proof disk, the bursting disk will rupture from the notch and release the pressure. The opening pressure of the explosion-proof valve is 0.4~0.8MPa. Therefore, the stability of the opening pressure of the explosion-proof valve is a key technical indicator.

Heju Stamping-Battery Rupture Discs Manufacturer with IATF16949certified

Dongguan Heju Precision Electronic Technology Co., Ltd. is an enterprise specializing in the production of battey bursting discs for new energy vehicles. It is one of the earliest battery rupture discs manufacturer in China. It has passed the three major certification systems of ISO9001, ISO14001, and IATF16949. Heju’s punching press machines to produce lithium battery rupture discs are mainly imported from Japan and Switzerland. Such as YAMADA, Jingli, KYORI, BRUDERER, and other brands. The testing equipment mainly includes the most advanced imported film thickness tester, magnified 1000 times to accurate monitoring blasting marks. We insist on providing customers with a daily output of one million to meet your production capacity needs. If you are choosing a realiable battery rupture discs manufacturer for your new project, please feel free to contact us.