Analysis of Metal Stamping Industry in China

Metal stamping is that use the punch press and stamping die to press external forces to the materials such as sheet and strip materials. It is a forming process method that produces plastic deformation or separation and obtains the desired shape and size. According to the process classification, it can be divided into two categories: separation process and forming process

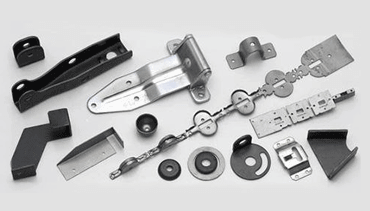

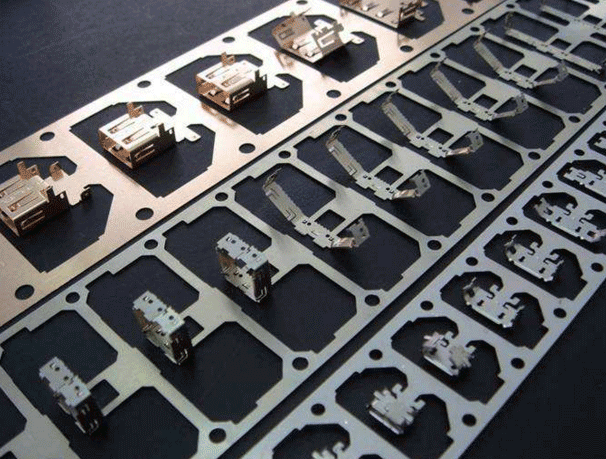

The separation process is also know as blanking, which purpose is to separate the metal stamping parts from the material and ensure the quality requirements of the separation section. The forming process is that make the sheet plastic deformation under the condition of not breaking the blank and obtain desired shape and size. Metal stamping processes contain blanking, bending, cutting, drawing, bulging, spinning and correction.. In actual production, a variety of processes are often applied to one metal part.

Metal stamping is the basic industry of machinery manufacture, and its development level reflects the competitiveness of a country’s manufacturing process technology. Car body, connector, chassis, fuel tank, radiator fin, the boiler steam drum, container shell, motor, electric iron core silicon steel sheet, apparatus and meters, household appliances, bicycles, office machinery, household utensils, and other products of manufacturing all need a great deal of metal stamping parts. Metal stamping is involved in aerospace industry, automobile manufacturing, electronic appliances, instruments and meters industry, equipment manufacturing industry, and many other aspects.

In recent years, China has become the world manufacturing center, especially in the automotive, communications, electronics and the rapid development of household electrical appliances and other industries. Metal stamping is the rapid growing demand.. Many multinational companies transfer to China at the same time, along with supporting factories moving to China. China accessories purchase quantity is rapidly increasing year by year, which lead to the rapid development of domestic related industries. In this context, China’s metal stamping industry, one of the manufacturing base industries, has also gained rapid development and rapid growth of market capacity.

Heju stamping is capable of executing a range of stamping techniques to fabricate parts from a wide range of metals such as stainless steel, copper, brass, aluminum, beryllium copper. We also provide plating options of nickel, Gold ,sliver, tin, bright zinc.

In addition, the organization is ISO 9001; ISO 14001 and ISO/TS 16949 registered and is committed to continual improvement with dimensional gauging and material testing. The management team at Heju continues to build on a solid foundation of quality products and on-time deliveries.