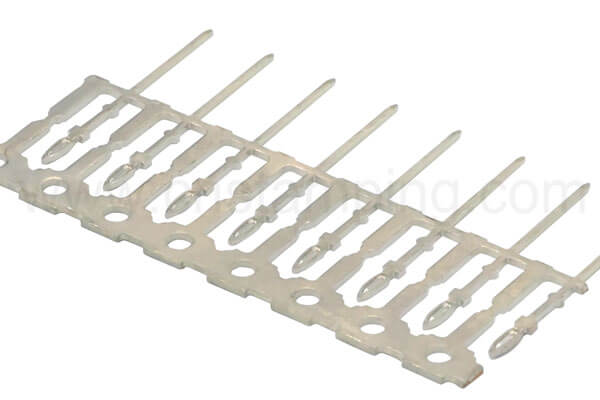

Customized Press-fit Terminals/Pins

Press-fit Technology

In the press fit technology, the elastic contact pin and the coating through hole (PTH) of the PCBs are the main components. The PTH is drilled into the layered circuit board by an electroplating process(usually copper plating), to form a circuit on the insert portion of the press-fit pin.

The main advantage is the high reliability of the connections and electrical contacts.

This press-fit pins design widely used in communication, automotive electronics and other fields.

Press-fit Connector Pins Stamping Manufacturer

We are a professinal OEM precision stampings manufacturer for various electronic components. Focus on providing press-fit terminals/ pins solutions for reliable, solderless, electrical connections for customers.

By designing and manufacturing high-speed progressive die with complex geometry and dimensional accuracy requirements, we have rich experience for compliant pin press fit projects, which can assist customer to develop final model based on the tooling feasibility.

Our Stamping Capabilities

Service

Equipped with more than 40 sets of high-speed imported punching machines (30T-160T) and dies processing equipment, which ensures production runs most efficiently and parts are 100% quality assured. We offer a full suite of metal stamping, metal forming, tooling and assembly services.

From sample testing to mass production to delivery, we monitor product quality throughout the process to ensure that each product meets the high standards of our customers.

The company currently has over 230 employees, of which R&D designers and mold technicians account for nearly 50%. The internal mentoring system as the core of the personnel training system, gathered many senior engineers and mold technicians, which has created an excellent team of stamping craftsmen in China.

Precision Metal Stamping

Other Production Parts

Hejustamping is a professional manufacturer who is focus on providing electronic components stamping solutions to global customers.

We produce stamping components include wire and cable connectors terminals, battery safety vents, stamped electrical terminals, press-fit terminals/pins, busbars, electrical spring contacts, micro deep drawn parts, electronic shielding components, lead frames, assemblies and more.

Widely used in new energy vehicle wiring harnesses and lithium battery, medical devices, consumables, chip packaging & testing, sensors and other fields.

The daily production capacity reaches millions units, with highly customized production capabilities to meet the special requirements of different customers.

Excellent Charactristics for Press-fit Pins for Pcb

- Unique Eye-of-the-Needle & Round Corner Design

- High reliability of the connections and electrical contacts

- Low press-in force, high retention force, good mechanical stability

- High elastic recovery

- Good compensation for pitch tolerances

- The minimum hole width can be half of the material thickness

- Straightness +/- 0.03mm, verticality +/- 0.03mm, Quality Consistency

Advantages for Compliant Pins Press-fit Design

- Fast manufacturing process

- No heat treatment required

- Low press-in force, high retention force, good mechanical stability

- Environmentally friendly

- Higher electrical reliability, more stable and increase the service life

- Disassembly and assembly are quick and easy, high efficiency and cost save

© Copyright 2012 - 2023 CNstamping All rights reserved.