Radiator Fins Production Craft Revolution: Metal Stamping to Replace Chemical Etching

A global well-known household appliance industry customer they had one kind of small hole product made by Chemical Etching, considering for their company environmental principle, they wanna do some improvement on the production. So they find Heju to find solution to make the part produced by stamping in this way to make the product more environmental and save cost at the same time.

About Chemical Etching

Etching is a technology that removes materials by chemical reaction or physical impact (thus, using a suitable chemical solution to etch away the part of the material that is not covered by photoresist (photosensitive film) to reach a certain engraving depth)

Disadvantage

- Not environmentally

- The hole wall is rough, shape is very easy out of control, and the solder paste penetration is extremely poor. Because during corrosion, the chemical solution not only dissolves the metal in the vertical direction, but also constantly etches the sidewall, making it difficult to obtain satisfactory opening shape and surface smoothness of the hole wall regardless of under-corrosion, over-corrosion, or proper control of the corrosion time. , Has a very adverse effect on the release of the pad.

- The position accuracy is low, and the hole size is not accurate. As light painting or photography is required to obtain the mask bottom plate, and exposure is required to complete the pattern transfer, the size of the final template is affected by multiple processes, and position errors are inevitable. At the same time, the accuracy of the bottom plate, the pattern transfer process, and the side corrosion make it difficult to control the opening size.

The Challenge

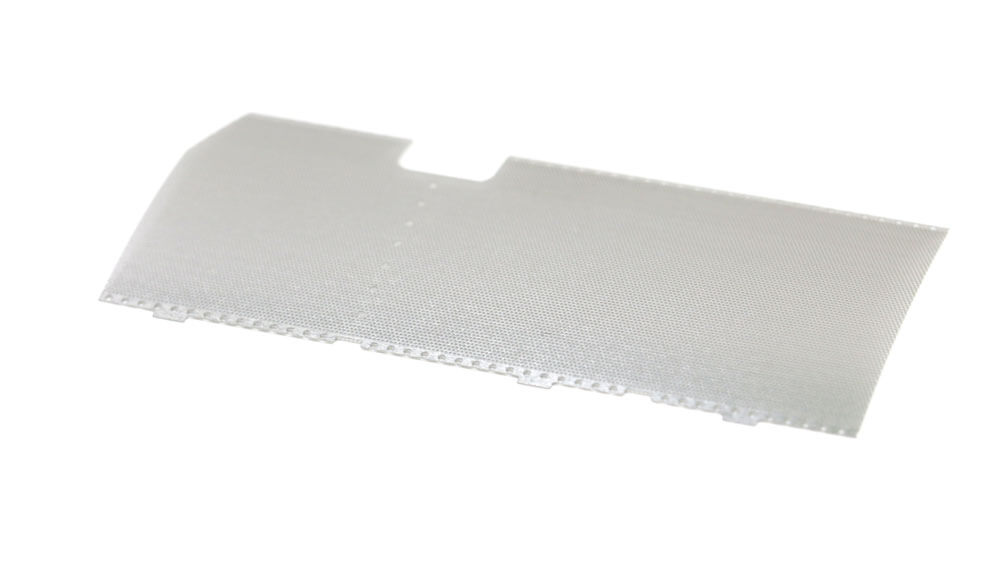

The mesh for producing this kind of small radiator fins is very small, and the hole wall needs to be smooth, the density between the holes must be kept at a certain distance, and the filterability must be kept consistent.

The Solution

Receiving customer’s request, our engineering team had a deep a communication with customer’s engineers, by using our advantages and experience in precision stamping technology (previously made small hole metal parts in earphones), we provide a complete replacement solution to change etching technology to metal stamping, of which we have also obtained patents for related technologies. You can click on Patent to view

Result

Through precision progressive stamping technology, we’ve helped customer to solve environmental protection problem and the advantages of continuous stamping are used for mass production, which greatly improved customer’s production cycle. At the same time, in the small hole technology, we can make the hole pitch in 0.2mm-0.5mm.

Our team has more than 30 years of experience and is capable to solving various technical problems of precision metal stamping. Help customers overcome product’s technical difficulties.

Technical Point

- Material: Copper, Iron, Aluminum, Stainless steel etc.

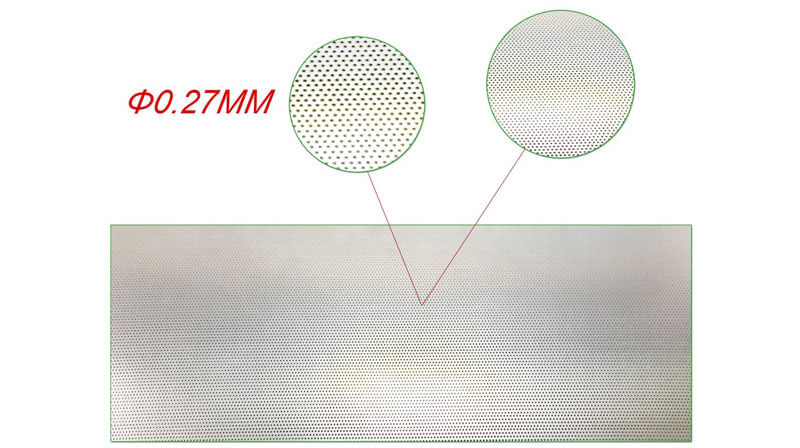

- Small hole size: Min. φ0.08mm

- High density: Hole pitch 0.3mm(17 thousand uniform fine holes in 50*80mm area)

- High precision: Tolerance control with +/-0.01mm,

Related Stamping Examples

Advantages of Progressive Die Stamping

1. Suitable for Mass Production Demand

The continuous die production speed (up to 1500 times/min) is higher than any other operation methods and processing types. If count on the number of the crankshaft press one-minute shot, the daily output can reach from 30,000 to 150,000 pieces.

2. High Accuracy for Product Dimensions

The dimensional accuracy of the stamping parts is guaranteed by the tooling and has exactly the-same characteristics, so the quality is stable and the interchangeability is good.

3. Save Materials, Energy Saving and Environmental Protection

Metal stamping processing technology generally does not require chemical corrosion, and do not produce any chemical waste after production, which is in line with the concept of environmentally friendly products. And there is no need to cut a large amount of metal like cutting, so it can maximize use materials and save material costs.

4. Easier Project Arrangement

This type of tooling is appropriately decomposed into simple shapes and arranged in different workstations, which can avoid the fragile parts of tooling structure and increase its lifespan, which can reach more than 300 million times.

5. Alleviate Hardening of Drawing Materials

When performing drawing processing in a progressive die, the drawing rate and the number of drawing times can be increased to ease material hardening degree and avoid the need for semi-finished product annealing during processing.

6. Safety Production

The progressive die is an automated die, which does not require manual operation during processing, and there is no possibility of harm to human body. When the feeder fails or other accidents occur, the press machine can immediately stop work to avoid punch damage.

Contact us immediately to learn how we can provide stamping solutions for your projects!

Get A Quote For Your Next Projects

No matter your project is complicated or simple, our experts will provide a solution, you will get an accurate quotation within 12 hours.

© Copyright 2012 - 2023 CNstamping All rights reserved.