Fine Blanking for Mobile Mechanical Parts

A manufacturer in the mobile phone industry wants to make a metal part, which can be used on camera of mobile phone. The customer have requirements on parts dimension tolerance and scratch free.

The Solution

After checking the customer’s requirements, engineers think fine blanking is better than general blanking and fine blanking can meet the technical requirements.

Technical Features

- Automaticallycombine traditional progressive punch machine with fine blanking die.

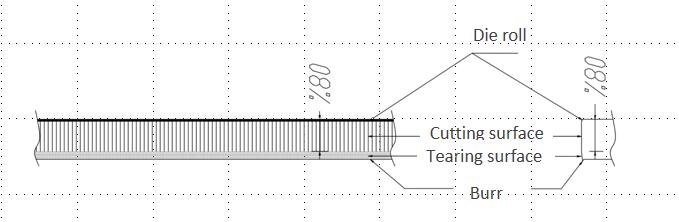

- Stamping smooth cut zone reaches more than 80% of material thickness.

- Small burrs

- High production efficiency

What is Fine Blanking?

Fine blanking is a kind of precision machining technology developed on the basis of general blanking. Both of them belong to the separation process, but fine blanking contains the special process parameters of the processing method. The die parts, using fine blanking, also have different quality characteristics. Especially, fine blanking and cold forming (such as bending, drawing, flanging, upsetting-extruding, counterbore, semi-piercing and extrusion, etc.) are combined. Fine blanking parts have been widely used in many fields, such as automobile, motorcycle, consumer electronics, electronics industry, etc. It replaced the parts previously used in general blanking, machining, forging and powder metallurgy processing. So it has technological advantages and economic benefits.

Contact us today to learn how we can deliver solutions for your project.

© Copyright 2012 - 2023 CNstamping All rights reserved.