What Influences the Life of Precision Terminals Die?

Influencing factors of precision terminal die life in different stamping process and external environment is various. Following comprehensive Analysis of the factors affecting die life in punching equipment and mold design:

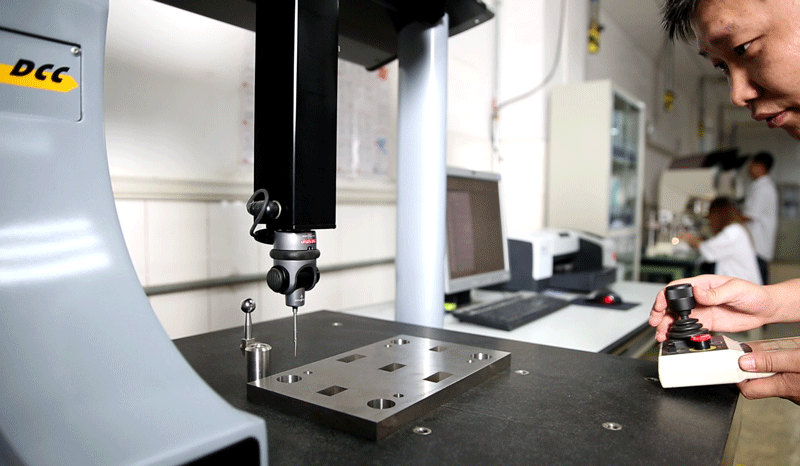

A. Punching equipment of precision stamping terminals

It is vital to stamping die life time of the precision and rigidity of punching equipment. The punching equipment with high precision and strong toughness can consumedly raise the stamping die life time.

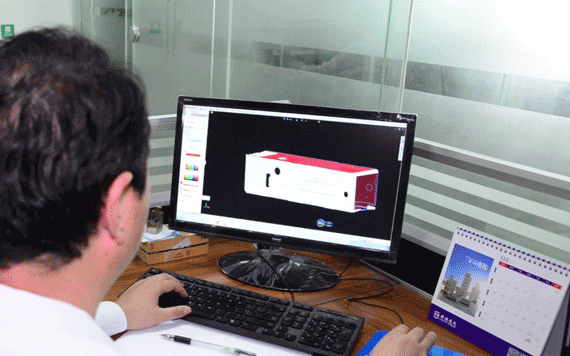

B. Mold design of precision terminals

1. The precision of guiding mechanism mold. Accurate and reliable guiding mechanism can reduce the wear of die parts and avoid the bite wounds of convex, concave die. Especially the absence of gap or small clearance blanking die, compound die and progressive die is more effective. In order to raise stamping die life, engineers must choose the guiding form and confirm the precision of guiding mechanism according to the requirements of process properties and precision of die parts.

2. Geometric parameters of die convex and concave die edge. The shape, fit clearance and the fillet radius of the convex and concave die have not only a great influence on the forming of the stamping parts, but also on the wear and life of the die. For example, the gap with the mold directly affects the quality of blanking stamping parts and stamping die life. If the requirement of stamping terminal accuracy is high, the smaller clearance value should be chosen; on the contrary, the properly bigger gap can improve the life of the precision terminal die.