Fakra Terminals: The Ultimate Solution for New Energy Vehicle Connectors

As the global automotive industry accelerates toward electrification, the demand for high-performance automotive connector terminals has surged. Among the critical components driving this revolution, Fakra terminals stand out as a game-changer for new energy vehicle connectors, offering unmatched reliability, durability, and precision in an era where efficiency and safety are non-negotiable.

Why Fakra Terminals Excel in New Energy Vehicles

New energy vehicle terminals must withstand extreme conditions—high voltages, rapid temperature fluctuations, and constant vibrations, while maintaining stable electrical connections. Fakra terminals are engineered to meet these challenges head-on. Crafted from premium materials and designed with cutting-edge technology, they ensure optimal conductivity and resistance to corrosion, even in the harshest environments.

Precision is key for automotive connector terminals. Fakra’s patented design minimizes contact resistance, reducing energy loss and enhancing the overall efficiency of electric vehicles (EVs). Whether for battery management systems, charging ports, or onboard electronics, Fakra terminals deliver consistent performance, making them a top choice for EV manufacturers worldwide.

Key Advantages of Fakra Terminals

- Superior Durability: Tested to endure over 10,000 mating cycles, Fakra terminals outlast conventional options, reducing maintenance costs and downtime.

- High-Temperature Resistance: Capable of operating in temperatures ranging from -40°C to 150°C, they ensure reliability in diverse climates.

- Vibration Resistance: Advanced locking mechanisms prevent loosening, which is critical for EVs exposed to dynamic road conditions.

- Customization: Fakra offers tailored solutions to fit unique new energy vehicle connectordesigns, supporting rapid innovation in the EV sector.

Applications in New Energy Vehicles

From battery packs to motor controllers, Fakra terminals are integral to the backbone of EVs. They are widely used in:

- High-voltage battery connectors: Ensuring safe power transmission between cells.

- Charging systems: Enabling fast charging compatibility without overheating risks.

- Sensor and signal circuits: Providing stable data transfer for autonomous driving systems.

The Future of Automotive Connectivity

As automakers push for longer ranges and faster charging, the role of automotive connector terminals becomes even more pivotal. Fakra’s commitment to R&D ensures its terminals stay ahead of industry trends, incorporating lightweight materials and innovative connectivity features. By choosing Fakra, manufacturers future-proof their designs while adhering to stringent global safety standards.

Conclusion

In the competitive landscape of new energy vehicle terminals, Fakra sets the gold standard. Its blend of innovation, resilience, and adaptability makes it the go-to solution for automakers aiming to lead the electric revolution. For engineers and procurement specialists seeking reliable automotive connector terminals, Fakra delivers not just components—but a foundation for next-gen mobility.

About Hejustamping

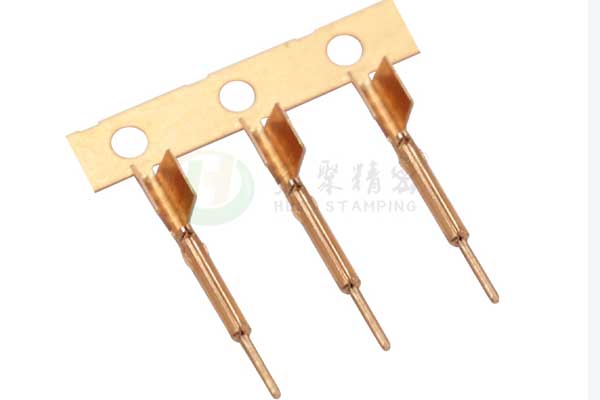

Dongguan Heju Precision Electronic Technology Co., Ltd. is a specialized manufacturer focused on the design and production of automotive connector terminals. In 2016, the company achieved IATF16949 system certification. We provides types of high-quality new energy vehicle connector terminals, stamping terminals, crimping terminals, crimp contacts/pins, etc. We combine 3D modeling and tool simulation with the best tools to provide our customers with tailor-made solutions to meet their complexity, functionality and custom design requirements. With more than 30 years of expertise and experience in die and metal stamping, we can achieve better performance than other stamping parts in our industry.