Blind-hole or Through-hole Press-fit Terminals

Press-fit terminals, as electronic connectors, are widely used in various electronic devices to achieve connections between circuits. In the design of press-fit connector pins, the design difference between blind-holes and through-holes has an important impact on their performance and application scenarios. The following is a detailed discussion of the difference between blind-holes and through-holes in press-fit pins/terminals. Aiming to provide readers with a comprehensive understanding and reference.

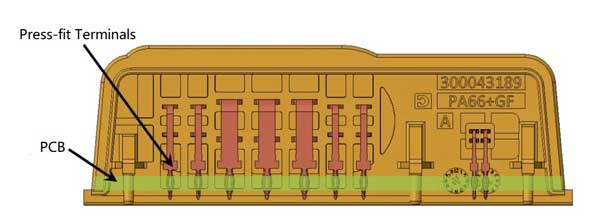

Basic Structure and Function of Press-fit Terminals

Press-fit terminal usually consists of a root, two elastic parts and a pin part. The elastic part is in the shape of a circular arc, and the two elastic parts are arranged opposite to each other to form a unique press-fit hole structure. This design enables the press-fit terminal to perfectly match the conductive hole on the circuit board (PCB board) through the elastic contraction of the elastic part during installation to achieve an electrical connection. Due to its unique structure and design, the press-fit pins for pcb has the characteristics of solderless connection, quick installation, no thermal stress and tight connection. It is widely used in various electronic devices.

Comparison Between Blind-hole and Through-hole Press-fit Terminals/Pins

Structural Differences

There are significant structural differences between blind-hole Press-fit terminals and through hole press-fit terminals. A blind-hole design leaves one end of the terminal closed, while a through hole design leaves one end of the terminal open. This structural difference leads to differences in application scenarios and performance between the two.

Connection Method

Blind-hole Press-fit Terminal Pins

Because the blind-hole can only be entered from one side, the installation and removal of the blind-hole press-fit pins usually requires special tools or devices. The elastic part is squeezed and elastically contracts. So that it perfectly matches the conductive hole on the circuit board (PCB board) to achieve an electrical connection.

Through-hole Press-fit Terminals

The installation and removal of the through-hole press-fit pin is relatively simple because it can be entered and passed from two directions.

Similarly, the elastic contraction of the elastic part cooperates with the conductive hole on the circuit board to achieve an electrical connection. However, the design of the through-hole makes the installation and removal process more flexible and convenient.

Application Environment

Blind-hole Press-fit Terminals

Commonly used in situations where it is necessary to avoid holes passing through the workpiece. Such as when the surface of the workpiece needs to be protected from corrosion or physical damage. In printed circuit boards (PCBs), blind-hole press-fit pcb pins are often used to connect the surface circuit and the inner circuit below without penetrating the entire board.

Through-hole Press-fit Terminals

They are more suitable for situations where objects or liquids need to pass between the two surfaces of the workpiece. On PCBs, through-hole press-fit compliant pins can be used to achieve conductive connections between different layers or for installing and removing components.

Conclusion

Press-fit terminals/pins are connection devices utilized for linking and contacting electronic products and circuit boards. The manufacturing process for these terminals often employs stamping technology, which offers several significant advantages. Firstly, stamping is a simple and efficient method that allows for the rapid completion of large-scale production tasks. Thereby enhancing overall production efficiency. Secondly, the continuous nature of the material during stamping ensures that the surface of the press-fit terminal pin remains smooth and flat. Eliminating the need for additional surface treatment and ultimately reducing production costs. Furthermore, stamping technology enables the production of press-fit terminals in various shapes. Catering to the diverse requirements of different products and enhancing market competitiveness.

Hejustamping

Dongguan Heju Precision Electronic Technology Co., Ltd. is a dedicated manufacturer specializing in the production of precision metal stamping parts. Such as press-fit terminals/pins, automotive terminals, electrical spring contacts, deep drawn parts, etc. Company has successfully obtained certifications in three major systems: ISO9001, ISO14001, and IATF16949. Dongguan Heju boasts a comprehensive quality inspection system. And provides electroplating support services, demonstrating a commitment to collaborating with customers to meet their specific product customization needs.